Packing Machine: Types, Benefits and Uses

Introduction

In the dynamic landscape of modern production, packaging machines have emerged as indispensable assets. They have revolutionized the way products are handled, enhancing efficiency, safety, and aesthetics. By automating the packaging process, businesses can ensure consistent quality and meet the high demands of production. This article delves into the world of packaging machines, exploring their types, benefits, and applications across various industries.

What are Packing Machines?

Packaging machines are sophisticated devices engineered to automate the packaging process. This encompasses a wide range of activities, including feeding, weighing, filling, sealing, printing and finished product transportation. These machines find applications in diverse industries such as food and beverages, pharmaceuticals, cosmetics, and consumer goods. Their primary function is to securely and efficiently package products, making them ready for distribution and sale. By replacing manual labor, packaging machines can execute these tasks at a much faster pace and with greater accuracy. This not only saves time but also ensures that each product is packaged uniformly, minimizing the likelihood of errors.

Types of Packing Machines

1. Multi-head Scale Vertical Automatic Packing Machine

Fully automatic vertical packaging machine is suitable for quick-frozen foods, dumplings, glutinous rice balls, fried dough sticks, meatballs, grilled sausages, fried chicken, steamed buns, snack puffed foods, shrimp crackers, corn flakes, nuts, peanuts, popcorn, cereal, melon seeds, petfood and dried fruits , agricultural and sideline products, grains, hardware accessories and other products packaging.

The vertical packaging machine and intelligent combination scale configuration can automatically complete the entire process of feeding, measuring, filling and bag making, date printing, inflation (exhaust), and finished product transportation, and automatically complete counting.

- Filling Range: 200g-2500g

- Packing Speed: 20-75bags/min

- Max Film Width: 420mm/520mm/730mm

- Film Thickness: 0.05-0.1mm

2. Inclined Anti-shatter Automatic Packing Machine

Jinchaoyue is the inventor of my country’s “anti-shatter inclined packaging machine” (inclined packaging machine). The anti-shatter inclined packaging machine is specially used for packaging goldfish wontons, lace dumplings, handmade dumplings, steamed dumplings, as well as biscuits, potato chips, wafer biscuits, corn flakes and other fragile, easy to rot, easy to agglomerate quick-frozen products and snacks. It occupies about 45% of the market share in the quick-frozen food industry. The products are well received and praised by customers, solving industry problems. The sales network covers the whole country and is exported to foreign markets such as Asia, Europe, North and South America, and Africa.

The drive control core is composed of PLC servo system, pneumatic control system, and ultra-large display touch screen, which maximizes the control accuracy, reliability and intelligence of the whole machine.

- Filling Range: 200g-2500g

- Packing Speed: 20-50bags/min

- Film Thickness:0.05-0.1mm

- Max Film Width:630mm/730mm

3. Horizontal Flow Pillow Packing Machine

Pillow packaging machine adops reciprocating horizontal sealing knife holder design. which can shorten the length of the packaging bag, seal the flat, effectively increase the sealing time, the sealing time is long, the temperature is low and the packaging speed is faster, and can adapt to the higher and thicker packaging film. The whole machine adopts six servo motion control system, and the reciprocating packaging machine can share 100 kinds of products of different specifications.

It is an automatic continuous shrink packaging equipment. It is widely used in the packaging of various food and non-food items with trays or five-tray boxes: frozen food, quick-frozen food, refrigerated food, daily necessities, chemicals, hardware accessories, various ice cubes, ice granules and granular materials.

- Packing Speed: 60-100bags/min

- Film Width: 700mm/850mm

- Film Thickness: 0.05-0.1mm

- Servo Motors: 8/10Pcs

4. Premade Bag Packing Machine

The automatic rotatry premade bag packaging machine is an efficient and automated packaging equipment. Through mechanized operation, it realizes full automation from bag taking, filling to sealing, greatly improving production efficiency and reducing labor costs.

It uses an up and down opening method to open the bag. It also has a positive pressure blowing function when opening the bag, which can completely blow open the packaging bag. At the same time, a pair of mechanical bag stretchers always hold the packaging bag when it moves to the unloading station. Open and do not leave until the unloading nozzle is inserted into the packaging bag. This ensures that the unloading nozzle can be 100% inserted into the packaging to avoid material leakage. At the same time, the bag opening device has a detection function. If there is no bag or the bag is not opened successfully, the material will not be unloaded, ensuring the accuracy of the unloading process.

- Packing Speed: 10-25bags/min

- Packing Bag Specification: Length:200-500mm Width:240-380mm

- Packing Material:Stand-up bags, zipper bags, four-side seal bags, three-side seal bags, paper bags (covered with paper), etc.

5. Sauce Packing Machine

Sauce packaging machine is widely used in the food industry and chemical industry, suitable for metering and packaging of liquids, solid-liquid mixtures, and highly viscous materials, such as: coconut, crystal balls, fruit fillings, salad dressing, chocolate sauce, cream, steamed bun fillings, meat fillings, fruit pellets, glutinous rice glue, coatings, greases, non-food detergents and other liquid and semi-fluid packaging.

- Packing Speed: 500g 20-25bags/min; 1000g 18bags/min; 5000g 6-8bags/min

- Filling Range: 500-5000g

- Packing Form: 3-side seal, vertical back seal

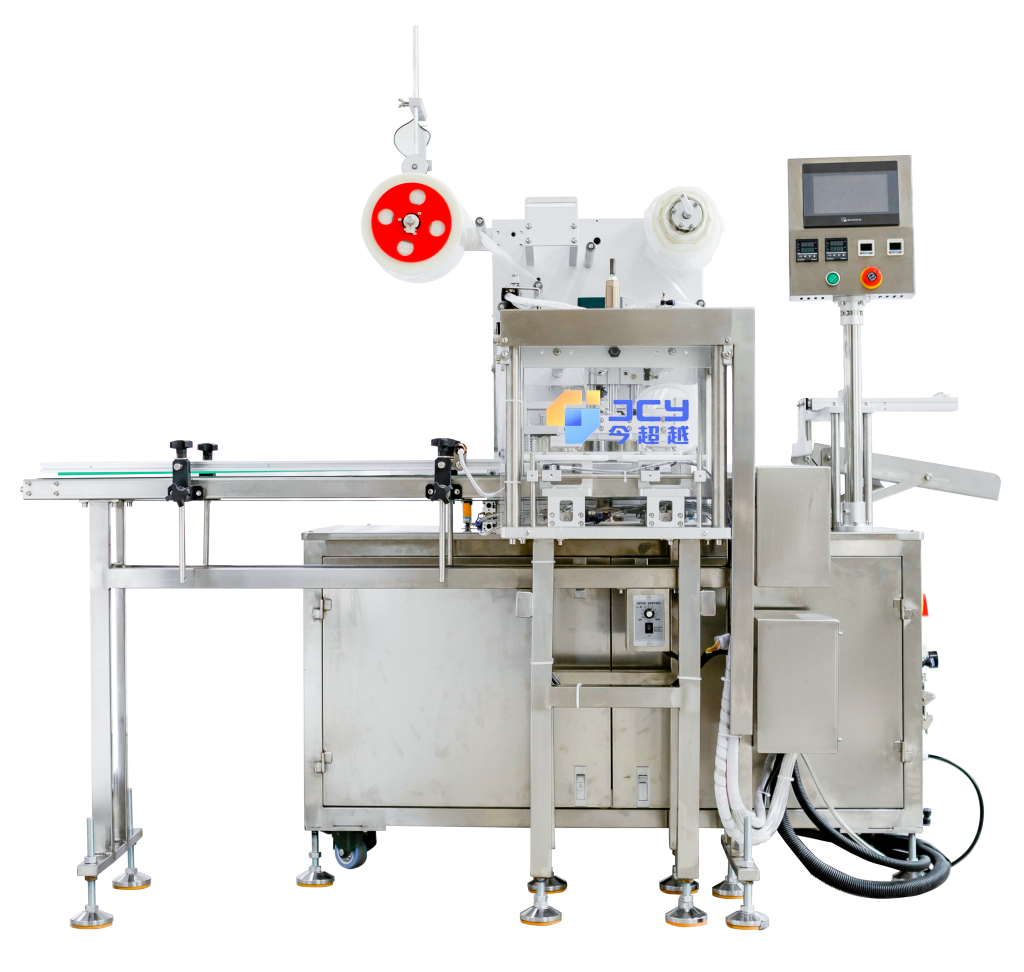

6. Box/Tray/Bowl/Cup Sealing Packing Machine

The disc laminating machine is suitable for box-type packaging of various types of food, and can automatically perform steps such as coding, sealing and packaging, slitting, and discharge of packaged products. The mold shape can be customized according to the packaging box style selected by the customer.

- Sealing Speed: 4-5 seconds per trip

- Temperature Control Range: 0-400℃

- Applied Material : PP/PE/PET (sealing material and container material are consistent)

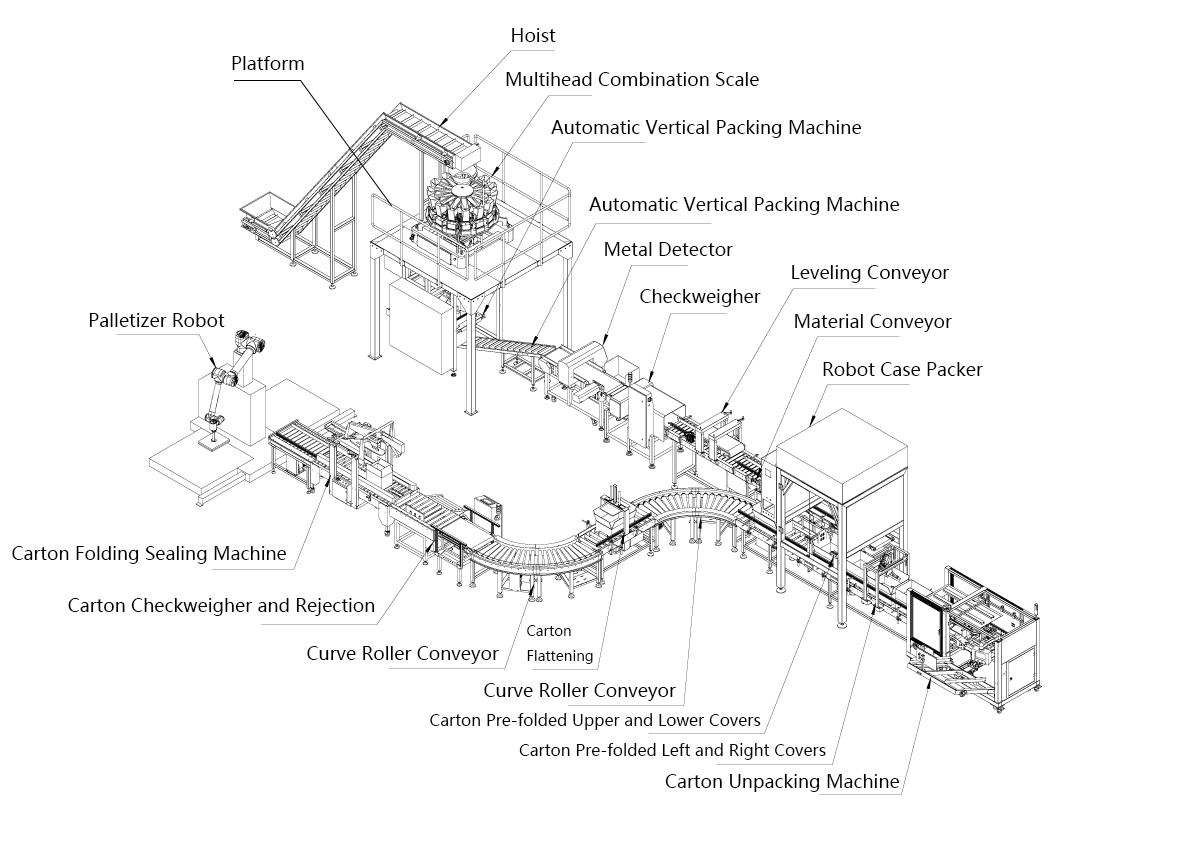

7. Multifunction Automatic Packing Machine Production Line

Automatic vertical packaging production line (packaging production line) adopts a vertical packaging machine designed on the basis of four servo control. Set automatic bag making, weighing, filling, sealing, printing, punching, cutting, sealing and other functions in one. Automatic completion of the whole process from feeding, metering, filling bag, printing date, output of finished products, high precision and high efficiency, saving labor costs. Widely used in quick-frozen dumplings, meatballs, steamed buns, fried dough sticks, wontons, frozen vegetables, frozen fruits, hamburger embryos, french fries, chicken legs, chicken steaks, siomai, steamed buns, pork chops, spring rolls, pies, snacks, candies, biscuits, melon seeds , nuts, peanuts, pet food, sea food, and other food and non-food spare parts packaging.

- Filling Range: 200g-2500g

- Packing Speed: 20-75bags/min

- Max Film Width: 420mm/520mm/730mm

- Film Thickness: 0.05-0.1mm

Benefits of Using Packaging Machines

Increased Efficiency

Packaging machines can process products at a much faster rate than manual labor. This increased production speed enables businesses to meet higher demand, ultimately leading to greater productivity and profitability.

Consistency and Quality

The machines ensure that each package is accurately fed, filled, bagged, date printed, sealed and delivered. This makes the quality and appearance of all products consistent, thus enhancing brand image and customer satisfaction.

Cost Savings

Although the initial investment in machinery can be substantial, the long – term savings on labor and reduced waste make packaging machines a cost – effective solution. By automating the packaging process, businesses can reduce the need for a large workforce and minimize product losses due to inconsistent packaging.

Improved Safety and Hygiene

Automated packaging reduces human contact with products, minimizing the risk of contamination. This is especially crucial in industries such as food and pharmaceuticals, where maintaining high hygiene standards is non – negotiable.

Versatility

Modern packaging machines are highly adaptable and can handle a wide range of products and packaging types. This flexibility allows businesses to respond quickly to market changes and consumer demands.

Sustainability

Many packaging machines are designed to use materials efficiently, reducing waste and promoting sustainability. This is in line with the growing global focus on environmental responsibility.

Conclusion

Packaging machines have become an integral part of modern production processes. Their ability to automate and streamline the packaging process offers numerous benefits, including increased efficiency, cost savings, and improved product quality. By understanding the different types of packaging machines available and their applications, businesses can make informed decisions when choosing the right equipment for their needs.