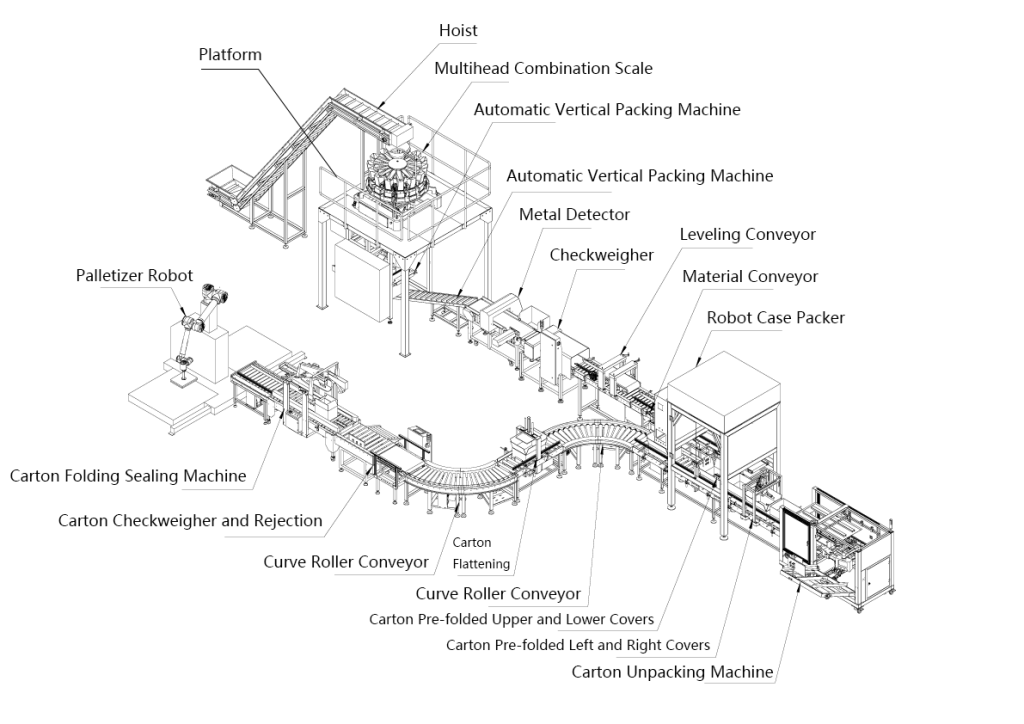

The entire process of the packaging production line

As a specialized mechanical equipment, fully automatic vertical packaging machinery can fully or partially realize the packaging process of products and commodities. Its core process covers the main steps of feeding, weighing, filling, bag making, sealing, date printing, finished product transportation, etc., to ensure that the product is properly packaged and its quality is protected. In addition, packaging machinery also includes weight detection, metal detection, stacking and other auxiliary processes before and after to ensure the consistency and efficiency of the entire packaging process. The organic combination of these processes makes packaging machinery play a vital role in modern industrial production.

Our company provides all equipment of the entire packaging system from vertical packaging machines (platforms, hoist, multi-head scales, vibrating bin)—finished product conveyors—metal detectors—checkweigher—conveyors—carton unpacking machine—robot case packers—conveyors—folding carton sealing machine—collaborative robot palletizers, and supports customization according to customer needs.

First of all, Vertical packaging machines (platforms, hoist, multi-head scales, vibrating bin) can package food or non-food. The packaged products are transported to the metal detector through the finished product conveyor for heavy metal detection. If they are unqualified, they will be rejected. The qualified products are then transported by the conveyor to the re-inspection scale for weight detection. The purpose is to check whether the weight of the packaged products is sufficient. Unqualified products will be rejected and qualified products will be transported to the robot case packer (before that, there will be a carton unpacking machine to open the carton and seal the bottom, and then transported to the robot case packer) for automatic case packing. The products in the carton are then transported to the folding case sealing machine for carton sealing. After sealing, they are transported to the robot palletizer for stacking.

The level of automation is constantly improving in the manufacturing industry, and the scope of application is expanding. The designed and installed automatic control packaging system has shown a very obvious effect in terms of improving product quality and production efficiency in the packaging machinery industry, as well as eliminating processing errors and reducing labor intensity. It is especially important for industries such as food, beverages, medicines, and electronics. The technology of automatic devices and system engineering is being further deepened and is being more widely used.